ERP for the Chemical Manufacturing Industry: An Overview

- What Is a Chemical Industry ERP?

- What are the Chemical Industry Challenges that ERP Systems Respond to?

- The Advantages that an ERP Software System Can Offer Chemical Companies

-

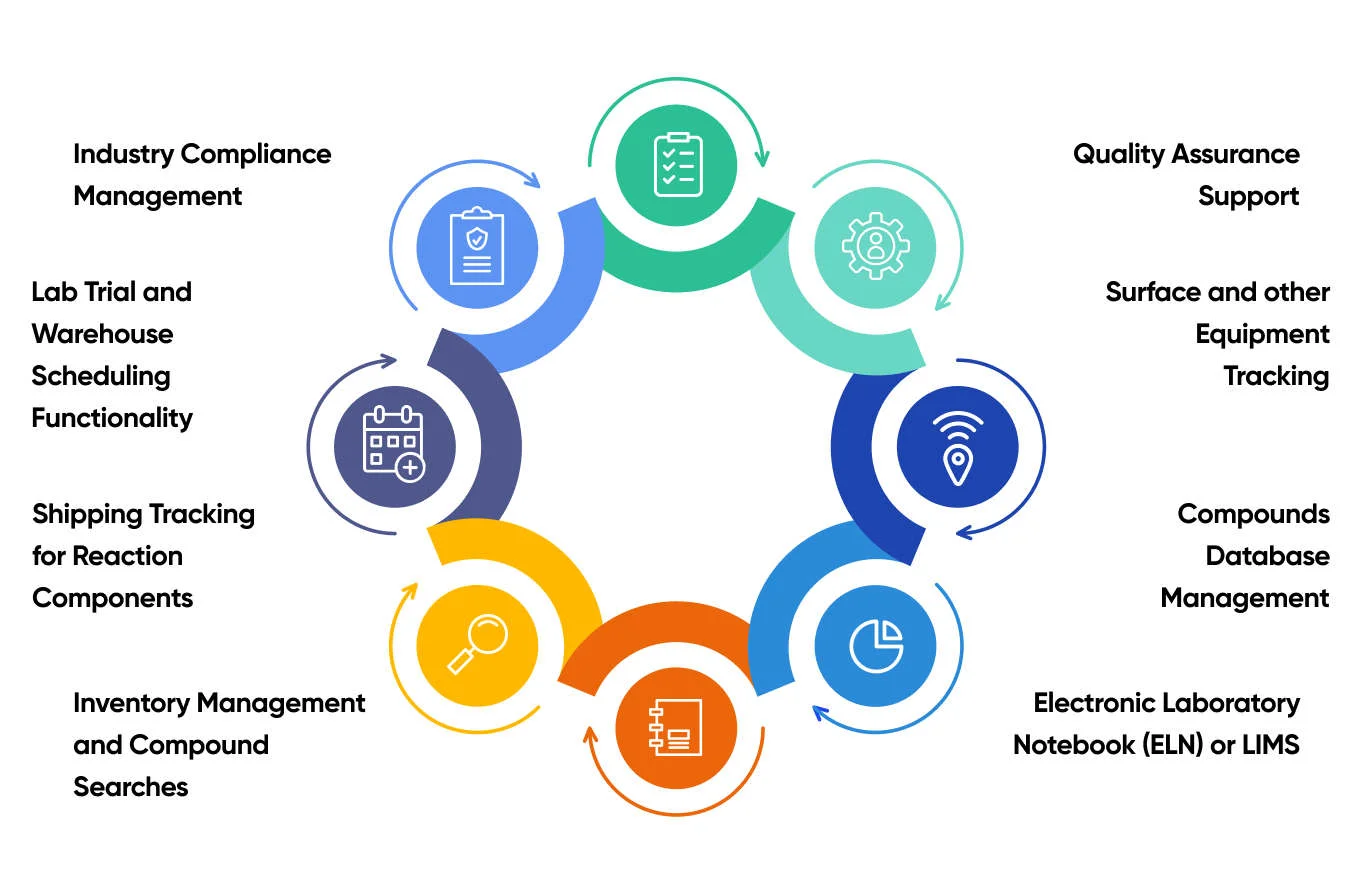

Must-Have Features for a Chemical Manufacturing ERP Solution

- Industry Compliance Management

- Lab Trial and Warehouse Scheduling Functionality

- Shipping Tracking for Reaction Components

- Inventory Management and Compound Searches

- Quality Assurance Support

- Surface and other Equipment Tracking

- Compounds Database Management

- Electronic Laboratory Notebook (ELN) or LIMS

- Conclusions

- FAQ

Whether you are running a contract research organization, a custom synthesis company, a specialty chemicals lab, or any other chemical industry business, tracking your resources is absolutely mandatory.

You cannot do your job well if you don’t know the number of your reaction components, surfaces, reaction costs, laboratory equipment, and other resources. And you should be 100% sure about their storage conditions, warehouse distribution, and logistics matters.

But how can you track all these parameters and even more?

A chemical industry enterprise resource planning (ERP) system is your perfect solution. Today, we will tell you how a quality ERP for chemical industry platform can help you manage your lab resources properly and how you can get a perfect ERP platform that fits your needs specifically.

What Is a Chemical Industry ERP?

Without further ado, let’s define the chemical industry ERP.

In brief, an ERP for chemical manufacturing is an application that incorporates the functionality that helps labs automate their resource-related processes.

Typically, such a platform includes functionality for batch resource planning, price tracking, storage condition management, logistic management, and regulation compliance.

Besides, ERPs for chemical manufacturers often include an Electronic Lab Notebook (ELN) and compound search engine as. Or, at least, ERP solutions perfectly integrate with such types of software.

The main purpose of such applications is to automate and improve the efficiency of resource planning in chemical laboratories.

And SoftFormance has relevant experience working on a top-quality chemical industry ERP system to a notable customer.

We used our favorite Python/Django combination to develop LifeChemicals, a chemical industry ERP system that incorporates an RDKit engine, enabling employees to use ELN and perform sub-structure searches for a range of chemical reactions, reagents, formulas, and related information.

The LifeChemicals platform provides prompt and precise search outcomes, accompanied by a comprehensive lab notebook. By facilitating efficient data management and process automation, this chemical ERP software aids chemical businesses in improving their overall productivity.

What are the Chemical Industry Challenges that ERP Systems Respond to?

The chemical industry is a very tricky field with too much information, both scientific and non-scientific, to be considered.

The most common challenges faced by custom synthesis companies, chemical process manufacturers, and contract research organizations include:

- Compliance with various industry regulations, such as MSDS, ISO9001, cGMP, OSHA & GHS;

- Reaction components’ storage, management, and tracking for their expiration dates;

- Tracking surfaces for batch process and other mission-critical equipment;

- Managing supply chains that are frequently very complex;

- Product trial planning and scheduling;

- Cost planning;

- Quality control over the results of chemical lab trials and obtaining Certificates of Analysis;

- Documentation, lab note, and custom synthesis formula management.

Fortunately, chemical ERP software provides solutions to all these challenges and even more.

The Advantages that an ERP Software System Can Offer Chemical Companies

Now that we have clarified the essence of chemical industry ERP systems, let’s define the most valuable advantages that you will get with this kind of software.

Improved Resource Planning

Imagine a situation when a custom synthesis company has taken an urgent order.

However, its managers find out that the company lacks components required for specific reactions.

As a result, the entire process takes too much time and the deadline for the order can be easily missed.

There won’t be such a situation if this company is using ERP software for chemical companies.

The point is that quality enterprise resource planning software helps this custom synthesis easily track its resources. And these resources can be checked in just a few clicks with a compound search engine for molecule subcomponents.

Better Reaction Storage Conditions

If you are storing reaction components or batch process surfaces in inappropriate conditions (wrong temperature, humidity, etc.), you may face unfavorable results when it comes to syntheses.

That’s why you should be 100% of the conditions in which you store components and equipment.

Chemical manufacturing ERP software will help you handle this problem because it allows you to constantly track storage conditions for all your resources.

Fortifying Supply Chain Management

If you want to get all components and equipment on time, you should obtain full control over your supply chain.

How can you achieve this?

The best solution is implementing the chemical industry ERP. It will help you track supply chain schedules.

Besides, this feature may help you integrate your chemical industry ERP with common logistics solutions and CRMs of your partners.

Dynamic Change Management

While running a custom synthesis company, a contract research organization, or any other chemical industry lab, you should always be prepared for unexpected changes.

For example, your reaction methods or formulas can change on the run.

So, your ability to quickly adapt to the changing situation becomes critical.

You can easily track all these shifts and plan your adaptivity with a chemical ERP solution. You will use it to store the required documentation, information on changes in your custom synthesis formulas, and plan workflow schedules.

Also, fast compound search, which is an important feature in most chemical industry ERP systems, will help you quickly find the components required for your changing formula.

Cost-Group Evaluation

While managing a custom synthesis lab, a specialty chemicals company, or any other chemical lab organization, you should not forget about the financial side.

Prices for equipment, reaction components, and other mission-critical materials change dramatically, which can become an unpleasant surprise.

To track all these changes and plan your budget more efficiently, you can quality ERP software for chemical manufacturing.

It will allow you to track market prices and plan your budget accordingly.

Must-Have Features for a Chemical Manufacturing ERP Solution

Chemical industry ERP solutions may include a great range of features. Let’s take a look at the most common functionality you can find in such software systems.

Industry Compliance Management

For many chemical industry labs, regulation compliance is one of the most challenging tasks.

There are just too many requirements and standards to consider.

A top-quality chemical industry ERP system will allow you to document your processes and track their compliance with various rules and regulations, such as OSHA, EPA, ISO, etc.

Lab Trial and Warehouse Scheduling Functionality

As long as most ERP chemical software systems help you track various warehouse processes and supply chains, they require scheduling features.

A quality ERP will include functionality for scheduling the supplies, inventory checks, equipment maintenance, and, in some cases, even lab trials and custom synthesis processes.

Shipping Tracking for Reaction Components

Here it goes about supply chain management functionality, which I have mentioned above.

Some chemical industry ERP systems can include interactive maps and similar components.

But the most convenient way is integrating such a solution with logistics software.

Inventory Management and Compound Searches

Well-organized inventory management is one of the main purposes of chemical industry ERP software.

That’s why such solutions cannot live without the corresponding functionality.

Here it goes primarily about inventory checklists, documentation on equipment, custom synthesis surfaces, reaction components, and expiration date tracking for different components.

Quality Assurance Support

Quality assurance is vital for custom synthesis organizations, contract research organizations, and chemical manufacturing labs.

A top-notch chemical industry ERP system includes functionality for sample checks and results tracking.

As a result, a chemical lab manager can easily use this data to automatically generate a COA (certificate of analysis).

Surface and other Equipment Tracking

One more important feature to look for in chemical industry ERP systems is equipment tracking.

Here it goes about implementing a dashboard for control over storage conditions and the use of various equipment.

You can leave notes about changes in equipment or all the times you need to repair your chemical industry laboratory equipment.

Compounds Database Management

Sometimes, when a formula has to be adjusted on the fly, you have no time to search for the required reaction components the traditional way.

That’s when a compound search engine comes in handy.

Integrations with compound search engines, such as RDKit, provide for more efficient molecule I/O, substructure searches.

An ERP system should provide a functionality allowing lab employees to find the required reaction components and the information on their storage in just a few clicks.

Electronic Laboratory Notebook (ELN) or LIMS

And, surely Electronic Lab Notebook (ELN), similar to the provided by PerkinElmer, or laboratory information management system (LIMS) are also very important parts of a specialty chemical ERP software.

An ELN will help you leave notes about reactions, results of custom syntheses, and any lab trials.

Meanwhile, LIMS is a more complex solution, often including resource planning, business insight, and lab trial management functionality.

It is the most vital digitization part for any custom synthesis or contract research organization.

And it often perfectly integrates with an ERP system or is integrated as its part.

Conclusions

So, ERP software for chemical industry is your safeguard from missed deadlines, non-compliance with industry rules and regulations, equipment breaches, and reaction component expirations.

Besides, it is your way to automate supply chains, custom synthesis management, lab trials, quality assurance, and many other processes.

Basically, it is the core component in the chemical industry lab digitization.

And whether you need to pick the right ERP solution or develop a business-specific chemical industry ERP from scratch, you can count on us!

FAQ

We recommend you consider whether this solution will cover your main chemical industry challenges. A quality ERP system includes the right functionality, such as compound searches, an electronic lab notebook, supply chain tracking, compliance management, equipment tracking, inventory management, and quality assurance automation.

Chemical industry ERP allows laboratories to ensure more efficient cost-group evaluation, equipment tracking, regulation compliance, resource planning, compound searches, and logistic tracking.

We use a great range of industry-specific technologies in chemical industry software development, including RDKit, Chemaxon, NumPy, and Chemotion.

Our team of specialists will help you leverage chemical industry ERP by finding the most suitable ready-made solution or developing your custom ERP system from scratch.

Thanks for the article on stating the importance and benefits of ERP to chemical industry.