The Best Chemical Manufacturing Software Solutions in 2023

In the chemical manufacturing industry, adherence to the safety protocols and regulatory requirements is essential. That is why in recent years, more and more companies started using specialty chemical manufacturing software to ensure that they meet all regulations and requirements, automate and streamline their processes, increase efficiency, and reduce spending. In 2023, there are several software solutions available that chemical companies can use: SAP, Oracle, Sage X3, Odoo, and CDD Vault. In this article, we will talk about these tools, their benefits, and main features.

What is Chemical Manufacturing Software

Chemical manufacturing software is the specialized software used to efficiently manage operations in the chemical industry. It is used by pharmaceutical, fertilizer, pesticide, cosmetic chemicals, construction chemicals manufacturing companies, etc. It provides various tools for tracking inventory, monitoring quality control, adherence to the latest regulatory requirements, and managing production schedules. Chemical manufacturing software is specifically designed to be easily customizable so it meets the needs and requirements of any chemical company.

Some chemical software can be easily integrated with Enterprise Resource Planning (ERP) software, Supply Chain Management (SCM) software, and Laboratory Information Management systems (LIMS). As a result, managing the manufacturing process will become faster, easier, and more efficient.

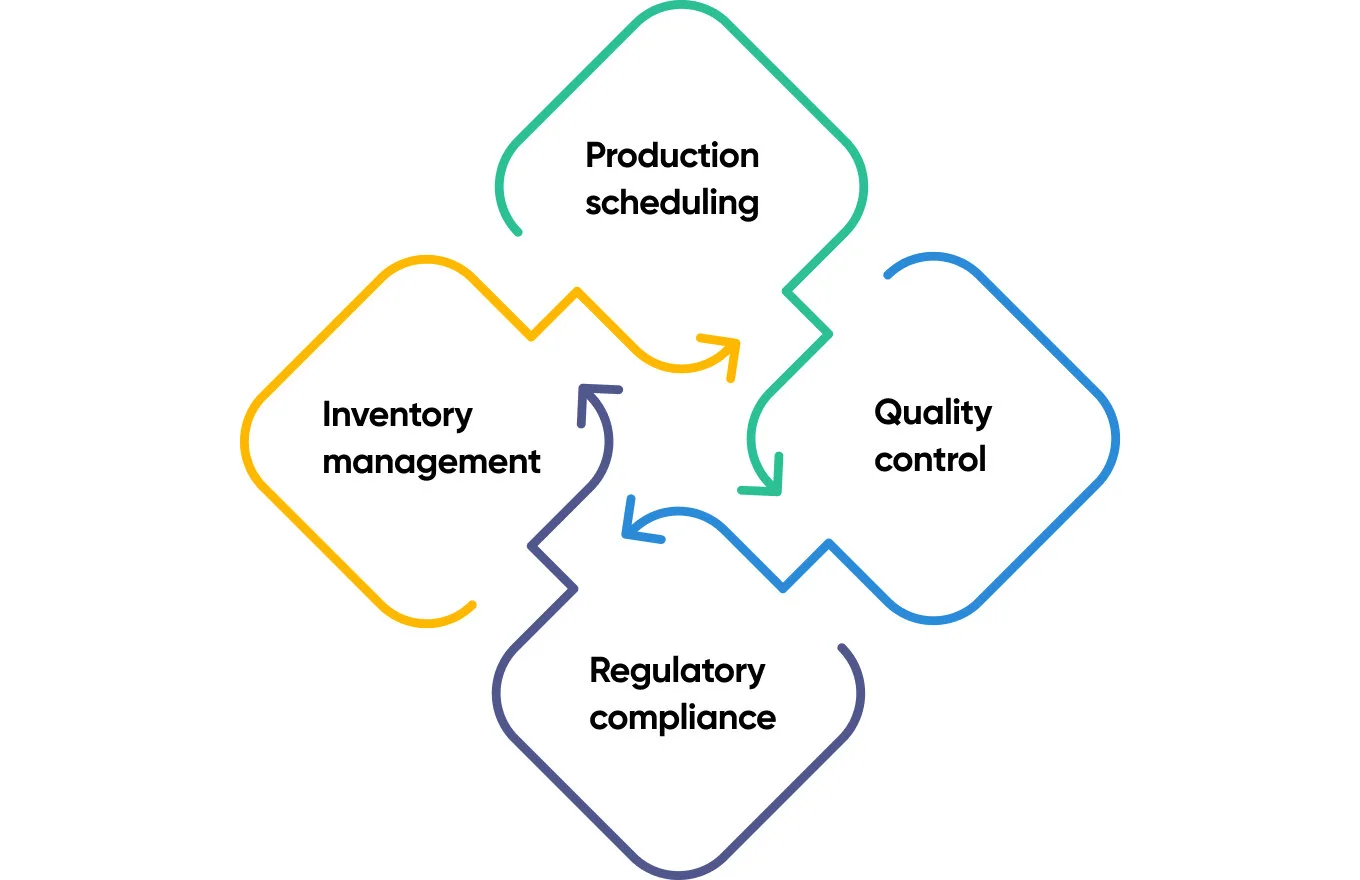

Chemical Manufacturing Software Features

Chemicals software is gaining popularity among chemical companies because of its features that help with inventory management, production scheduling, quality control, and regulatory compliance.

Inventory management

This feature allows manufacturers to track raw materials and finished products and make sure that all needed materials and tools are available for production. Moreover, this tool helps control the stock levels more efficiently and ensure that they are at optimal levels. It collects data about the inventory, keeps track of everything, and allows manufacturers to avoid issues with stock levels.

Production scheduling

Another essential feature that helps streamline operations is production scheduling. It helps plan and schedule production runs to ensure that everything process is carried out as efficiently as possible. As a result, it decreases the likelihood of errors, reduces the time of production, and helps minimize waste and increase productivity.

Quality control

This feature helps deal with one of the most critical aspects of chemical manufacturing. Quality control is the basis of any chemical production, and chemical manufacturing software helps ensure that all processes meet the quality requirements. This feature includes tools for tracking product quality, monitoring and analyzing data, tracking performance, and identifying gaps and areas of improvement.

Regulatory compliance

This feature helps ensure that the manufacturers comply with up-to-date regulations and standards in the industry. It is achieved by tracking regulatory compliance, various reporting tools, and more. As a result, chemical manufacturers can save costs and maintain compliance easier.

Popular Chemical Manufacturing Software

The most widely used software for the chemical industry include SAP, Oracle, Sage X3, Odoo, and CDD Vault. All of them have their unique features and tools, and the choice depends on the manufacturer’s needs, requirements, and the current state of their business.

SAP

SAP is a software company that provides solutions for various types of industries, including chemicals. It provides chemical manufacturers with software that helps manage their complex business processes, improve efficiency, and streamline all operations.

The main solution for the chemical industry offered by SAP is SAP S/4HANA Cloud. It is designed specifically to help chemical manufacturers adopt digital transformation. The tool provides companies with real-time insights into all their operations, which helps them make more informed decisions faster. Moreover, the tools help companies optimize their supply chain operations and reduce spending.

SAP Transportation Management solution helps chemical manufacturers control their logistics and transportation. SAP Environment, Health, and Safety Management solution help ensure that all operations comply with safety and environmental regulations.

Oracle

Oracle provides software solutions for the chemical industry, covering supply chain management, financials, regulatory compliance, logistics, and production planning.

Oracle E-Business Suite, one of the main solutions provided by the company, includes modules like quality management, manufacturing, inventory management, and more. These modules allow chemical companies to manage their processes more efficiently, ensure that the products meet the quality criteria, and optimize the supply chain operations.

Other solutions that can be used by chemical companies are Oracle Transportation and Oracle Agile Product Lifecycle Management. Oracle Transportation helps chemical manufacturers manage their logistics and transportation, and Oracle Agile Product Lifecycle Management helps them manage regulatory compliance and product development.

Sage X3

Sage X3 is an ERP chemical software. Its modules are designed to help chemical companies deal with supply chain management, inventory management, quality control, customer relationships, production planning, etc. All these modules are integrated, allowing chemical manufacturers to manage their business processes from start to finish.

Sage X3 is often used by companies that need to manage complex supply chains. This software allows them to track inventory easier, schedule production and reports, and monitor deliveries in real time.

This software also has advanced analytics capabilities. Manufacturers can get real-time insights into business operations, identify areas of improvement, and make more informed data-driven decisions.

Sage X3 is incredibly customizable so the manufacturers can tailor this software according to their needs.

Odoo

Odoo is an ERP that is designed for businesses of all sizes that want to improve their efficiency and automate processes. It is an excellent solution for chemical manufacturers who want to manage production, inventory, sales, and finance.

Odoo allows for managing complex production processes by helping manufacturers define all stages of the production process, track raw materials, manage their finished products, and schedule production and shipment.

Moreover, it can be used to monitor the quality of production, reduce waste, save resources and money, and improve productivity. All of this can be achieved with the help of Odoo’s powerful inventory management tools and quality control modules.

Odoo’s inventory management tool helps optimize storage facilities and track inventory movements. Chemical manufacturers can set up automatic stock replacements, manage warehouse operations, and ensure that there are no issues with lot and serial numbers.

Its quality control module allows manufacturers to set up quality tests, ensure adherence to regulatory requirements, and meet the highest standards of quality and safety.

CDD Vault

CDD Vault is a cloud-based platform that was designed specifically for chemical manufacturers and businesses involved in drug development. It helps companies organize their production processes, manage clinical trials, and ensure security and compliance with safety regulations.

With CDD Vault, companies can collect, store, and analyze large amounts of data related to compound libraries, experimental results, and chemical structures.

Moreover, it is a powerful tool for visualizing data as its tools can be used to generate real-time insights, identify patterns, and optimize experimental designs. As a result, manufacturers can make more informed decisions faster, collaborate more efficiently, and streamline research processes.

CDD Vault has been built to help manufacturers meet the highest standards of security and quality. These standards include HIPPA and GDPR. Thus, manufacturers can manage and store sensitive data and be sure that it is stored safely and protected against disclosure or unauthorized access.

Trends in Chemical Manufacturing Software

Nowadays, chemical manufacturing is developing rapidly, taking into account the new advances in technology and industry trends. Depending on what is happening in the industry, the trends in chemical manufacturing software also change. Here are a few of them:

- Artificial Intelligence and Machine Learning: AI and ML have become increasingly important in the chemical industry. They help analyze large volumes of data faster, make predictions, and improve product development processes.

- Cloud-based solutions: Cloud-based solutions help chemical manufacturers access the data easily, scale up, and lower IT costs. Moreover, it is possible to update cloud-based software more easily so that manufacturers always have access to the latest tools and capabilities.

- The Internet of Things: The IoT is used to control and monitor production processes, such as pressure, temperature, and humidity. As a result, it helps reduce waste, optimize processes, and improve product quality.

- Compliance and regulations: Chemical industry compliance and regulatory requirements are becoming more complex. That is why software solutions must be able to help manufacturers meet those requirements and ensure adherence to the highest quality standards. This includes data security, privacy, and compliance with regulations like GHS and REACH.

- Integration with other systems: Chemical manufacturing software can be integrated with other systems. For example, it can be integrated with financial management or supply chain management.

Benefits of Chemical Manufacturing Software by Softformance

At SoftFormance, we have been developing software for various industries for over 10 years. We take a unique approach for each client and ensure that the software we develop meets all their needs and requirements. Here are the benefits of our chemical manufacturing software:

- Highly customizable to meet the requirements of every client, ensuring that the software is tailored to their workflows.

- Enhanced quality control and adherence to safety regulations.

- Improved efficiency through streamlined processes and reduced manual data entry.

- Real-time data collection and analysis.

- Integration with systems like ERP and CRM software to provide a seamless experience and automate processes.

- Customizable dashboards and reporting tools.

Conclusion

Wrapping up, chemical manufacturing software is going through serious changes these days, influenced by new industry trends, developments in technology, and strict safety and quality regulations. Chemical manufacturers that use this type of software benefit from its features that help with inventory management, quality control, and production scheduling.

These solutions help companies streamline their processes, reduce waste, and save time and money. Thus, if you have been looking for a way to optimize your production processes and improve adherence to safety protocols, you can either choose among the existing software tools online or contact us for a consultation on custom development.

FAQ

Chemical manufacturing software is a type of software designed specifically for businesses in the chemical industry. It is used to manage and optimize various aspects of the manufacturing process, including production planning, formula management, quality control, regulatory compliance, and supply chain management.

Some examples of software commonly used in the chemical industry include SAP, Oracle, CDD Vault, Odoo, and Sage X3.

The specific needs and goals of the business, the software’s features and capabilities, its scalability and integration capabilities, its cost and return on investment, and its level of user-friendliness and support.

In the field of chemical engineering, some of the most frequently utilized software options include process simulation software such as Aspen HYSYS, ChemCAD, and COMSOL Multiphysics, as well as data analysis and visualization software such as MATLAB and Tableau.

One of the best chemical blog I ever seen.. please keep sharing like this…

TQ for sharing the wonderful information…